Stepwise approach

Implementation of OPS requires input of plenty of detailed local data from the various stakeholders mentioned above and careful planning and study.

Feasibility study

There are many examples of feasibility studies being undertaken prior to implementation of an OPS project. Examples include those carried out at the ports of Los Angeles, Long Beach, Rotterdam and Amsterdam.

The OPS calculation tool contains all the relevant cost items and data needed to develop a feasibility study. It should be borne in mind that it is impossible to quantify all the benefits accruing from OPS. for example the value of improved working conditions onboard and at terminals. These effects should be taken in into due account, however.

The following two issues should always be carefully analyzed, as these will generally have the greatest impact on the feasibility of an OPS project:

- costs of local power supply

- distribution of vessel types and frequency of calls

“Shoreside power for ships is not a one-size-fits-all solution. It requires substantial infrastructure on the landside and retrofitting ships on the water side. It is not a cost-effective solution for ports where the same vessels do not call frequently throughout the year”. Linda Strout, Deputy Chief Executive Officer, Port of Seattle.

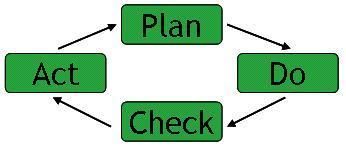

PLAN-DO-CHECK-ACT

When implementing an OPS project, the PLAN-DO-CHECK-ACT-approach can be used as a management tool.

In the submenus this stepwise approach to coordinated OPS implementation is illustrated. For a more elaborate version, click here.

PLAN – plan your implementation of Onshore Power Supply by doing a feasibility study

- Take advantage of the experience and knowledge available at other ports,in reports and at authorities on OPS.

- Find out what vessel fleet in your port would be most suitable for OPS,preferably frequent-calling vessels with long port stays and offering the greatest emission reduction potential.

- Determine the best technical approach by collecting data on electrical systems, voltages, frequencies, fuel quality and fuel consumption on the vessels in question.

- Estimate the emission reduction potential using various scenarios:

-vessels burning heavy fuel oil (where legal) compared with use of alternative energy like wind power (preferably) or the energy mix available from the local utility company.

-vessels burning low-sulphur distillate fuel compared with use of alternative energy like wind power (preferably) or the energy mix available from the local utility company. - Estimate the cost effectiveness and environmental effectiveness.

- Present your findings and check interest among key stakeholders.

- Evaluate incorporation of OPS when constructing new quays/wharfs.

DO – implementing your OPS project

- Select the vessel fleet/shipping line with the greatest cost effectiveness and environmental benefits.

- Choose the appropriate technical solution

- If possible, purchase energy produced from a renewable energy source to achieve a maximum environmental net benefit.

- Agree on the commercial set-up between port authority, terminal operator and shipping company.

- Establish a Memorandum of Understanding with your client or mandate OPS as a requirement in new contracts/leases with new terminal operators.

- Implement the technology on both the quayside and the vessels.

- Set up a communications plan and share your work/efforts with community,customers, employees, local authority, etc.

CHECK – measure the results

- Monitor progress (economically and environmentally).

- Evaluate how OPS was implemented (strengths and weaknesses).

ACT – do potential improvements

- Based on evaluation and monitoring, introduce any necessary improvements.

- Keep on communicating the results and achievements with the port community and stakeholders.

- Whenever possible, apply the technology in all new quays/wharfs.

- Whenever possible, discuss the development of OPS, the environmental potential and the economic incentives with authorities, politicians, shipping lines and maritime organizations.

- Collaborate with other ports and share experience.

- If possible, extend the use of OPS to other vessels in your port.

- Combine OPS with other emission reduction solutions like train shuttles, ecodriving for working machines, etc. OPS is not the only environmental mitigation measure available.